Language

Views: 0 Author: Site Editor Publish Time: 2022-10-21 Origin: Site

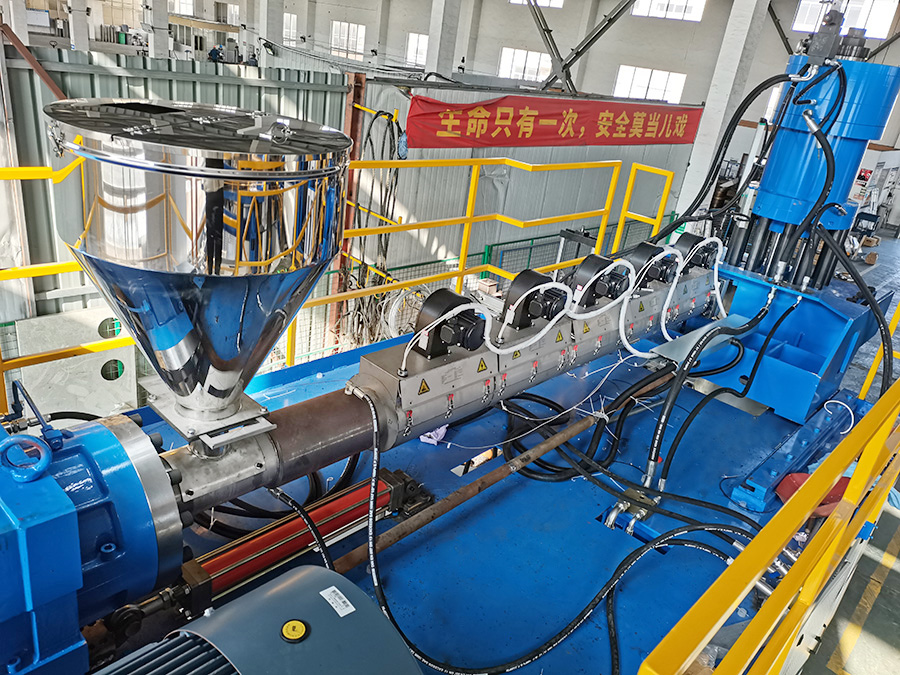

Maintenance of temperature controller of large blow molding machine

The temperature controller of the large blow molding machine is part of the energy storage heating system of the die head. Today, we mainly look at the maintenance of the temperature controller of the large blow molding machine.

In recent years, some changes have taken place in the heating system of large blow molding machines, using PLC temperature modules instead of thermostats, and using solid state relays instead of contactors. However, the heating equipment has not changed much. The update and improvement of this technology provide convenience for the integration of the electronic control system and reduce the connection between the electronic control system and the components. Using advanced electrical control technology, the existing temperature control system is completely replaced by an integrated temperature electrical control system.

Maintenance of temperature controller of large blow molding machine

Special Note: Use downtime to clean the instrument and keep it clean.

1) Ensure that the wiring of the thermostat is firm to prevent the wiring and connection points from affecting normal work.

2) Check whether the temperature sensor wiring is firm.

3) In hot weather conditions, pay attention to ensure that the ambient temperature of the temperature controller is within the normal operating temperature range. When the ambient temperature is too high, effective cooling measures should be taken.

4) Under humid conditions, if the equipment is in a stopped state, power should be supplied to the temperature instrument regularly to prevent the instrument from malfunctioning due to moisture. After a long downtime, double check and power on for 4-6 hours, then start running.

5) Replace the deactivated temperature controller and temperature sensor in time. Check whether the model and voltage of the temperature controller match the temperature control range, and whether the wiring is correct.